An engine in model year 2025 stands as the powerhouse of a vehicle, transforming energy into motion. Most vehicles rely on engines that convert heat from fuel combustion into mechanical output. Advanced electric and hybrid engines now deliver greater efficiency and power while reducing carbon emissions. Studies show battery electric engines outperform others in energy efficiency and environmental impact. This shift highlights the engine’s evolving role, as manufacturers focus on cleaner, more powerful solutions for modern transportation needs.

Engines in 2025 convert energy from fuels, electricity, or hydrogen into motion, powering vehicles and machines efficiently.

Advanced engine technologies improve fuel efficiency, reduce emissions, and increase reliability through innovations like hybrid systems and digital controls.

Electric and hybrid engines offer cleaner alternatives with instant torque, lower maintenance, and zero tailpipe emissions, supporting a sustainable future.

New fuels such as hydrogen, ammonia, and methanol help reduce carbon footprints while traditional fuels remain important during the transition.

Regular maintenance and smart driving habits boost engine efficiency and performance, helping drivers save fuel and protect the environment.

An engine in 2025 serves as the central unit that converts energy into usable power for vehicles, machinery, and even ships. This device takes energy from sources like fuel, electricity, or hydrogen and transforms it into motion. The main purpose of an engine is to provide reliable and efficient movement for different applications. People encounter engines in cars, trucks, motorcycles, ships, and industrial machines. Each engine uses a specific process to turn energy into mechanical work, depending on its design and the energy source.

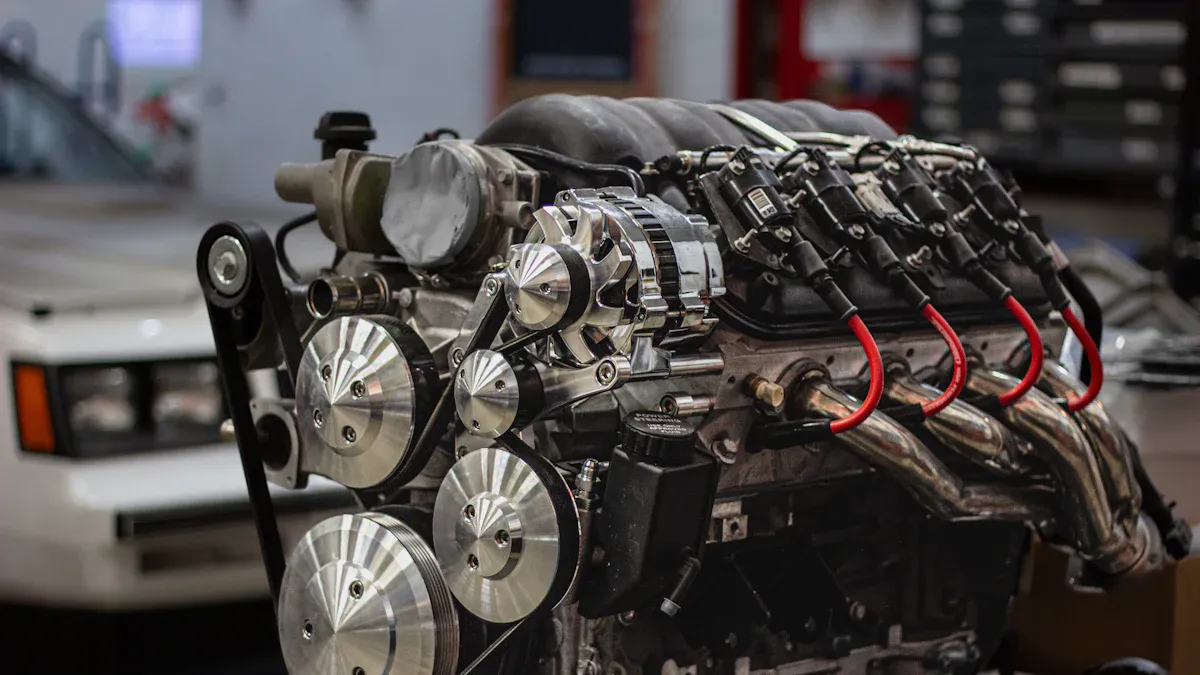

Engine technology in 2025 covers a wide range of engine types. These include traditional internal combustion engines, electric motors, hybrid systems, and engines powered by alternative fuels such as hydrogen or ammonia. Each type offers unique benefits for performance, efficiency, and environmental impact. The choice of engine depends on the intended use, fuel availability, and emission requirements.

Engines in 2025 display several advanced features that set them apart from earlier models. Manufacturers focus on improving efficiency, reducing emissions, and increasing reliability. The following table highlights some of the most significant technological advancements introduced in 2025:

Technological Advancement | Description | Significance |

|---|---|---|

Ammonia-fueled two-stroke marine engine by WinGD | First engine of its kind installed on a 46,000 m³ LPG/ammonia carrier | Reduces carbon emissions in marine transport |

HR18 HEV hybrid powertrain by Horse Powertrain | Fully integrated hybrid drive unit for low emissions | Advances hybrid powertrain technology |

Rotating detonation engines (RDEs) | Improved combustion efficiency for rockets and turbines | Breakthrough in propulsion and power generation |

Plasma electric rocket engine prototype | Uses magnetic plasma acceleration for higher thrust | Enhances aerospace propulsion |

Scania Super 11 engine | Lighter and more energy-efficient than previous models | Improves heavy-duty engine performance |

GM sixth generation V-8 engines | Stronger performance and better fuel economy | Combines power with efficiency |

JCB hydrogen engine | Approved for non-road machinery in the EU | Supports hydrogen as an alternative fuel |

WinGD largest methanol-fueled engine | Ten-cylinder engine for container ships | Expands methanol use in marine engines |

Note: These advancements show how engine technology in 2025 addresses both performance and environmental concerns.

Key features of engines in 2025 include:

Enhanced efficiency through improved combustion and digital integration.

Advanced emissions control systems, such as DEF injection, that increase reliability and meet stricter standards.

Lighter engine designs that reduce fuel consumption.

Hybrid and electric options that lower carbon footprints.

Digital connectivity for remote monitoring and predictive maintenance.

Manufacturers like Cummins, Volvo, and Detroit optimize the entire powertrain, not just the engine, to improve fuel economy and reduce emissions. Updates such as better thermal management, precise fuel injection, and reduced friction help engines run cleaner and last longer. Modern after-treatment systems allow some diesel engines to produce exhaust cleaner than the air they take in, especially in urban areas.

US fuel efficiency standards for 2025 target an average of 54.5 miles per gallon. These standards help reduce global warming emissions and save consumers money. Life cycle assessments show that while electric vehicles have higher production costs, improvements in internal combustion engines remain important because these engines still dominate global transport.

The main engine types in 2025—internal combustion, electric, hybrid, and alternative fuel engines—offer choices for different needs. Each type brings new features that support cleaner, more efficient, and more reliable transportation.

Every engine in 2025 relies on advanced energy conversion to deliver power. The process starts with a source of energy, such as fuel, electricity, or hydrogen. Internal combustion engines use chemical energy from fuel. Electric engines use electrical energy stored in batteries. Hybrid engines combine both methods. Scientific principles like thermodynamics and electromagnetic induction guide these conversions. Thermodynamics explains how engines turn heat into mechanical work. The Carnot efficiency principle sets a limit on how much heat can become useful power. Material science also plays a role. New materials, such as graphene, help engines convert waste heat into electricity, boosting overall power output.

Innovations in 2025 have changed how engines handle energy. LAVA’s new thermodynamic cycle stands out as a major breakthrough. This closed-loop system lets engines recover more waste heat and store renewable energy more efficiently. As a result, engines now use less fuel and produce more power from the same amount of energy. These improvements help engines meet strict environmental standards while maintaining strong performance.

Note: Modern engines use scientific advances to convert energy more efficiently, leading to better power and lower emissions.

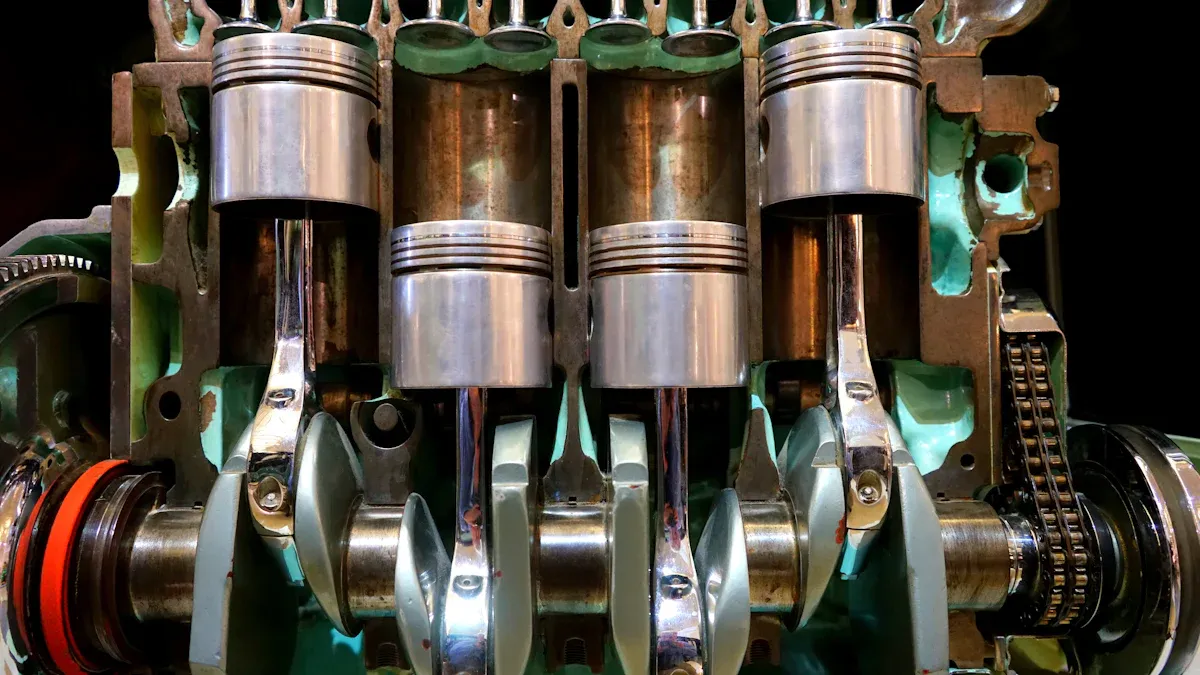

Engines create power by transforming energy into motion. In an internal combustion engine, burning fuel pushes pistons. These pistons turn a crankshaft, which then moves the wheels. Electric engines use magnets and coils to create motion directly from electricity. Hybrid engines switch between both systems to maximize power and efficiency. The main goal is to deliver smooth, reliable motion for vehicles and machines.

Power output depends on how well the engine converts energy. Better energy conversion means more power for the same amount of input. Engineers measure power in units like horsepower or kilowatts. High power allows vehicles to accelerate quickly and carry heavy loads. Improved engine designs in 2025 give drivers more control and better performance, while also reducing fuel use and emissions.

Internal combustion engines remain a major force in the 2025 market. These engines use fuel, such as gasoline or hydrogen, to create power by burning it inside the engine. The four-stroke engine continues to dominate, especially in passenger vehicles. Manufacturers have improved cylinder configurations, with four-cylinder engines leading the market due to their balance of efficiency and adaptability. In-line engines hold the largest revenue share, while V-type engines grow quickly in popularity for luxury and performance vehicles.

Cylinder Configuration | Description | 2025 Improvements/Trends |

|---|---|---|

Inline | Cylinders in a straight line; efficient | Inline-6 engines return in SUVs and sedans |

V Engines | Cylinders in a V shape; compact, powerful | Turbocharged V6s replace V8s for emissions |

Flat/Boxer | Opposed cylinders; smooth, low center | Used for handling, despite packaging limits |

To meet Euro 7 standards, internal combustion engine designs now include advanced emission controls, particulate filters, and lighter materials. Hydrogen internal combustion engines also emerge, using special aftertreatment systems to reduce NOx emissions. Despite the rise of electric vehicles, many regions still rely on internal combustion engines due to infrastructure and consumer demand.

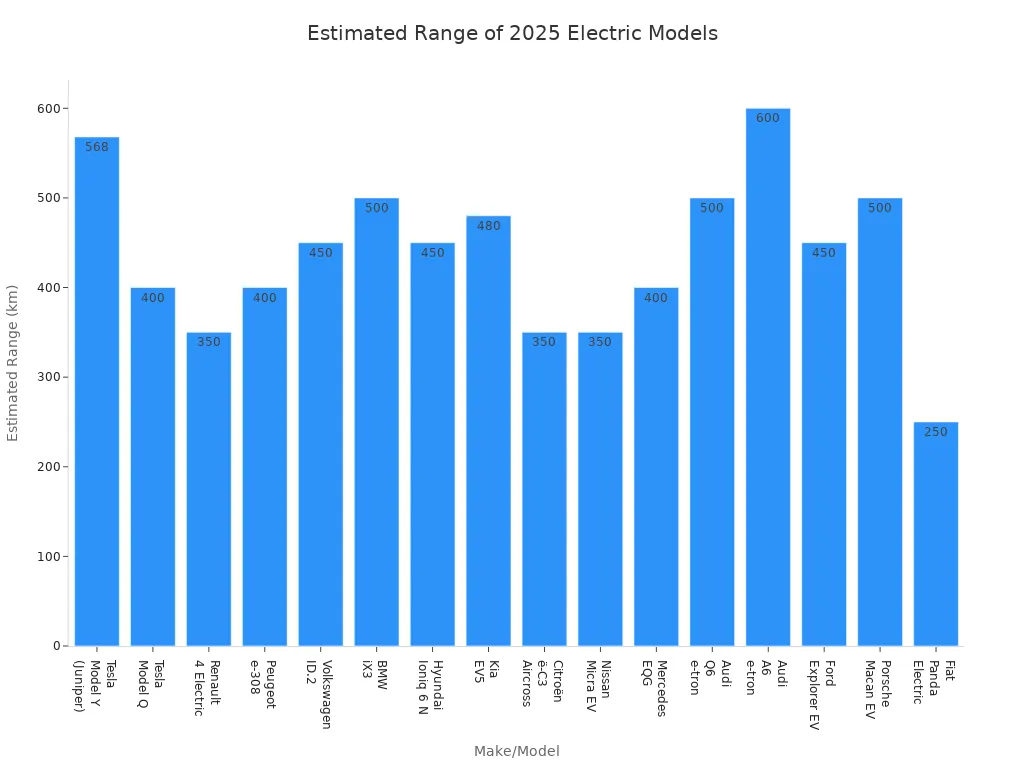

Electric engines have transformed the powertrain landscape in 2025. These engines use batteries to store and deliver energy, providing instant torque and smooth acceleration. New models, such as the Tesla Model Y (Juniper), BMW iX3, and Hyundai Ioniq 6 N, showcase the latest electric powertrain advancements.

Make/Model | Range (km) | Power (hp) | Release Date | Price (€) |

|---|---|---|---|---|

Tesla Model Y | ~568 | ~350 | May 2025 | From 55,000 |

BMW iX3 | ~500 | ~300 | Late 2025 | 55,000–60,000 |

Hyundai Ioniq 6 N | ~450 | ~641 | Late 2025 | 60,000–65,000 |

Volkswagen ID.2 | ~450 | ~180 | 2025 | 20,000–25,000 |

Battery technology now includes lithium-sulfur and sodium-ion chemistries, enabling faster charging and longer ranges. Electric engines also benefit from AI-driven powertrain management and advanced recycling methods, making them more sustainable.

Hybrid engines combine internal combustion and electric powertrains to maximize efficiency and performance. The 2025 Porsche Cayenne Hybrid uses a turbocharged engine and an electric motor, offering up to 74 km of electric-only range. Hybrid systems recover energy during braking and use it for electric driving at low speeds.

Hybrid turbochargers with electric motors reduce turbo lag and improve throttle response. Advanced fuel systems, such as LPG direct injection, further lower emissions. Parallel hybrid systems, including hydrogen-diesel dual-fuel engines, allow flexible operation and ultra-low emissions. These hybrid engines adapt to different driving needs, supporting both power and sustainability.

Electric motorcycle engines in 2025 deliver instant torque and rapid acceleration. Manufacturers like Zero, Harley-Davidson LiveWire, and Energica lead the market. These motorcycle engines use batteries for power, offering ranges around 160 km and fast charging in 1–2 hours.

Feature/Aspect | Electric Motorcycle Engines (2025) | Internal Combustion Engines |

|---|---|---|

Power Source | Battery-powered, improving range/charging | Gasoline-powered |

Torque Delivery | Instant torque, rapid acceleration | Builds with engine RPM |

Maintenance | Very low, fewer moving parts | Regular maintenance needed |

Sound | Quiet or artificial | Loud, distinctive |

Emissions | Zero at vehicle level | CO₂ and NOx produced |

Performance Example | ~110 hp, 190 Nm, ~160 km range | ~117 hp, 93 Nm, ~280–300 km |

Motorcycle engines now use lightweight materials and 3D printing for better efficiency. Hybrid and hydrogen motorcycle engines are under development, showing the future direction of motorcycle technology. Riders benefit from low maintenance, quiet operation, and zero emissions, making electric motorcycles ideal for urban environments.

Engines in 2025 continue to rely on traditional fuels for power, especially in transportation and industry. Crude oil remains the dominant source, accounting for about 54% of the market. Refined into gasoline and diesel, crude oil fuels most cars, trucks, and buses. Diesel supplies 81% of energy for trucks and buses, while gasoline provides 11%. Coal still plays a role in power generation, holding a 27% market share, though its use is declining in some regions. Natural gas is gaining popularity because it offers higher fuel efficiency and lower emissions compared to gasoline or diesel. Policy initiatives, such as India's plan to boost natural gas from 6.7% to 15% by 2030, encourage industries to adopt cleaner fuels. Aviation and shipping engines rely almost entirely on fossil fuels like jet kerosene and marine fuels.

Fuel Type | Market Share (2025) | Usage Details and Notes |

|---|---|---|

Crude Oil | ~54% | Main fuel for transportation and industry |

Coal | ~27% | Used in power generation, especially in Asia Pacific |

Natural Gas | Growing share | Cleaner profile, expanding use in engines for power generation and heating |

Fossil Fuels (overall) | ~84% | Majority of global primary energy consumption |

Note: Natural gas engines help diversify energy sources and reduce reliance on imported oil.

Sustainable energy sources are transforming how engines operate in 2025. Solar power and wind energy have become the lowest-cost resources, driving clean energy adoption. Clean energy now generates over 40% of global electricity, with solar doubling its output in three years to exceed 2,000 TWh. Many industries and data centers use renewable energy to power electric engines, supporting fuel efficiency and reducing emissions. Advanced technologies like green hydrogen and long-duration energy storage provide clean power for engines around the clock. Partnerships and federal policies accelerate the commercialization of these solutions, making sustainable energy more accessible for engine applications.

Solar and wind power support electric engines in vehicles and machinery.

Green hydrogen and advanced solar cells offer new options for clean engine operation.

Renewable energy integration increases fuel efficiency and lowers environmental impact.

Energy storage technologies play a key role in engine performance and fuel efficiency. Lithium-ion batteries remain the standard for electric engines, offering high energy density and fast charging. New variants, such as Li-Polymer and Li-Sulfur, improve safety and efficiency. Alternatives like sodium-sulfur, zinc-air, and magnesium-ion batteries provide sustainable and cost-effective options. Solid-state batteries promise longer lifespan and enhanced safety for electric engines. Hybrid energy storage systems combine batteries with supercapacitors, delivering rapid power and long-duration storage. Smart grids and virtual power plants use advanced storage to balance energy flow and support renewable integration. Recycling and second-life applications for batteries help address raw material scarcity and promote sustainability.

Lithium-ion batteries dominate energy storage for electric engines.

Solid-state batteries and hybrid systems improve safety and fuel efficiency.

Smart grids optimize energy use for engines powered by renewables.

In 2025, the automotive industry continues to measure engine power using horsepower. Horsepower represents the rate at which an engine performs work, with one horsepower equal to about 745.7 watts. The Society of Automotive Engineers (SAE) introduced a new power test standard this year. This standard ensures that power measurements for all powertrain types—combustion, hybrid, and electric—are accurate and consistent. Compact cars usually have engines with 70 to 130 horsepower, while high-performance vehicles can exceed 300 horsepower. The updated SAE test reflects real-world performance, helping consumers compare motorcycle engines and other vehicles more reliably.

Engine efficiency in 2025 depends on both technology and maintenance. Regular oil changes, clean air filters, and prompt attention to warning lights keep motorcycle engines running smoothly. Drivers improve fuel economy by removing extra weight and using cruise control. Modern powertrain systems, including hybrid and electric options, use AI-driven controls and eco-driving modes to boost efficiency. U.S. light-duty vehicles now show higher average fuel economy, as reported by official agencies. Manufacturers use lightweight materials and advanced aerodynamics to further enhance performance. The 2025 Ford Escape, for example, offers better fuel economy and smoother acceleration than its 2024 version, thanks to improved engine calibration and powertrain design.

Regular maintenance increases motorcycle engine efficiency.

Smart driving habits and route planning save fuel and reduce emissions.

New technologies like hydrogen fuel cells and solid-state batteries promise even greater efficiency for future motorcycle engines.

Engines in 2025 produce fewer emissions than in previous years, but internal combustion motorcycle engines still emit greenhouse gases and particulates. Advances in combustion systems, turbocharging, and aftertreatment solutions like diesel exhaust fluid help reduce pollutants. Electric motorcycle engines eliminate tailpipe emissions, especially when powered by renewable energy. New regulations finalized in 2025 require up to 90% reductions in nitrogen oxides and 75% reductions in particulate matter for many engine categories. These rules push manufacturers to adopt cleaner fuels, advanced aftertreatment, and hybrid-electric powertrain technologies. The industry also faces stricter fuel economy standards, driving innovation in engine design and manufacturing. As a result, motorcycle performance tuning now focuses on both power and environmental responsibility.

Note: The shift toward electrification and hybridization in motorcycle engines marks a major step in reducing environmental impact and improving overall performance.

Engines in 2025 deliver reliable power for cars, trucks, and motorcycles. They use advanced technology to improve performance and reduce emissions.

Electric vehicles and hydrogen fuel cells help lower pollution and offer new choices for drivers.

Motorcycle engines now last longer and need less maintenance because of smart diagnostics and better materials.

AI and software upgrades make engines safer and more efficient.

People benefit from cleaner air, better fuel economy, and more options for transportation. Engine innovation shapes daily life and supports a sustainable future.

Engines in 2025 use advanced materials, digital controls, and cleaner fuels. These engines offer higher efficiency, lower emissions, and better reliability. Manufacturers design each engine to meet strict environmental standards and provide strong performance for modern vehicles.

Electric engines deliver instant torque and smooth acceleration. They require less maintenance and produce zero tailpipe emissions. Internal combustion engines still power many vehicles, but electric engines lead in efficiency and environmental benefits.

Yes. Many engines now run on hydrogen, ammonia, or biofuels. These alternative fuels help reduce greenhouse gas emissions. Engine technology adapts to support cleaner energy sources and meet global sustainability goals.

Hybrid engines combine electric motors with internal combustion engines. This setup allows the engine to switch between power sources. Regenerative braking and smart controls help save fuel and lower emissions.

Engines in 2025 produce fewer emissions than before. Electric and hybrid engines help reduce air pollution. New regulations push manufacturers to design engines that protect the environment and support cleaner transportation.